We thank EAA Technical Counselors Bill Larson and Greg LePine who have been present nearly every build session of this project.

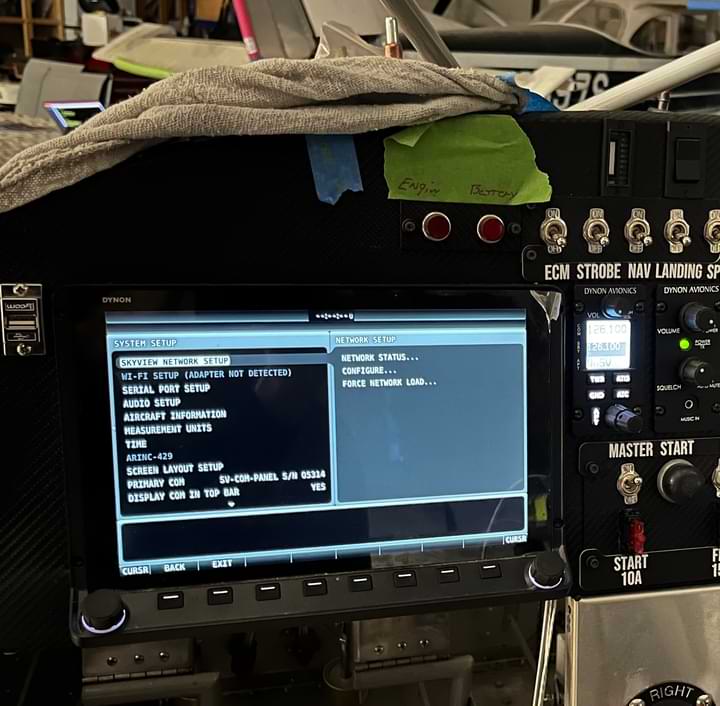

1 hr: Charlie - Continue EFIS set up; have finished about all we can do for now. - Begin to trim windscreen. 1641 hr cummulative

2 hr: Abel - Finish installing aft windows. - Fit PTT switches to handles. 1640 hr cummulative

2 hr: Samuel, Julian, Charlie, Abel - Begin installing aft windows. - Continue to configure HDX ECU screens. - Try to install PTT handles. Decide we need better momentary switches. 1638 hr cummulative

2 hr: (mentors only, no teens this weekend) - Discuss windscreen installation. - CAN bus to ECU is now working: Dynon hadn't included the CAN wires in its harness. ECU sensors appear incorrect? 1630 hr cummulative

1.5 hr: Charlie, Samuel, Hope - Install last SkyView network cable. - Update SkyView software in the airplane. - Shorten seat cushion fastening screws in co-pilot seat pan. - Try to install copilot seat; strip nutplate; begin repairs. - Identify CAN wires; decide where to mount; not sure about ground wire. - Install COM antenna and cover for belly hatch. 1628 hr cummulative

2 hr: Julian, Charlie - Install pilot seat. Seat cushion will be too thick for most pilots. - Power up the electrical Master for the first time. - Test electrical systems. All lighting circuirts work. - Test intercom with two headsets. Works. - Elevator trim and its indicator work correctly. - Flaps work correctly. Minor interference at right inboard mass balance. - Begin to configure Dynon avionics system. - All three Sky View Network devices are visible (EMS cable not yet ordered). - Configure all 4 serial ports. ELT format is not yet known. - Transponder is not replying to HDX. Connector had two pins in wrong positions. Fixed. 1623 hr cummulative

(Due to the holidays, there was no build session the previous week.) 0.5 hr: Charlie, Samuel 2 hr: Julian - solder up the headphone and mic jacks 1619 hr cummulative

(Due to the weather, there was no build session the previous week.) 1 hr: Charlie 2 hr: Jude, Abel - Wire transponder to HDX. - Start building COM harness. 1616 hr cummulative

1 hr: Charlie, Julian, Samuel - Wire the GPS and ADS-B-in to the HDX. Test flaperon travel again. 1611 hr cummulative

2 hr: Alex, Jude - Torque down, and mark so, flaperons, etc. - Make new aileron travel limit tab and install; torque down. Done. - Resolve problem with landing light: Power supply is too weak. - Electical wiring: Belly strobe, landing, both nav lights and tip strobes, with sync. 1608 hr cummulative

1 hr: Bobby 2 hr: Samuel, Abel - Install some network cables. - Try to assemble ELT D-sub; have to rework the shell. - Finish torque and mark flaperon push/pull tubes. One bolt was too short; replace. 1604 hr cummulative

1 hr: Jude 2 hr: Abel, Charlie, Samuel - Verify continuity of aft to forward wiring runs: trim motor, nav lights, strobes, fuel senders. - Find the landing light is defective, with half the elements out. - Decided to add ELT remote to panel, so run two extra wires aft. - Begin to bundle aft wiring runs into one cable. - Begin to install aileron limit tabs in control tunnel. 1599 hr cummulative

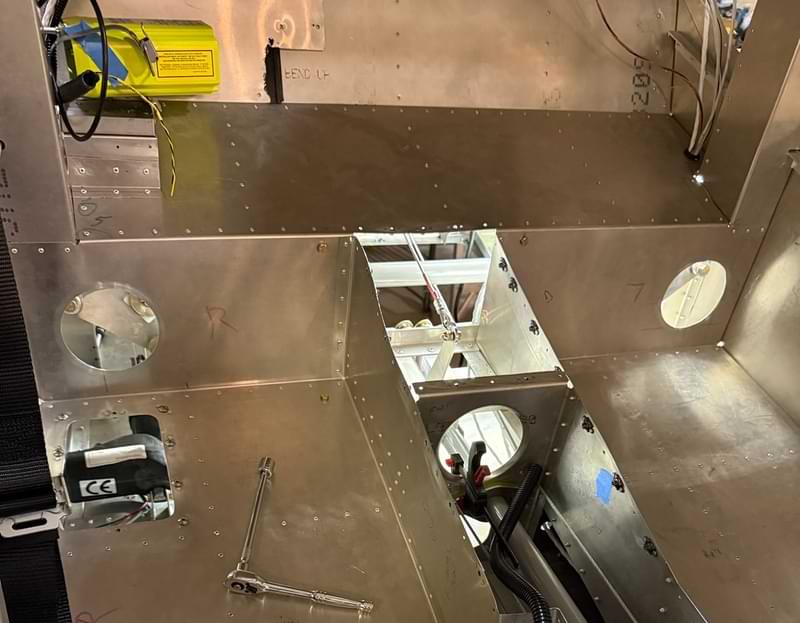

1 hr: Abraham - Seat interferes with the belts. Lower the bolt for the inboard attach point. 1592 hr cummulative

2 hr: Samuel, Abel, Charlie - Install outer seatbelt anchors. Install seatbelts. - Continue adjusting flaperon rods. (What a pill.) - Add access panels to flaperon bellcrank. 1591 hr cummulative

2 hr: Charlie 1 hr: Samuel - Continue rigging flaperons. Binding at the bellcranks is observed. 1585 hr cummulative

1 hr: Julian - Route aft wires to cabin. 1582 hr cummulative

2 hr: Jude 1 hr: Able - Flaperons are now functioning but a few clearance issues remain. - Track down some wiring runs. 1581 hr cummulative

1 hr: Samuel 2 hr: Samuel, Jude - Continue installation and rigging of the flaperons. 1578 hr cummulative

1.5 hr: Samuel, Able, Julian - Continue fitting flaperons to both wings. 1575 hr cummulative

(There was no build session the previous week.) 1.5 hr: Zee, Ankith, Samuel - Continue flaperon installation. Join right wing sections. Work on left wing root hinge pin. - Wiring at the panel and firewall. 1570 hr cummulative

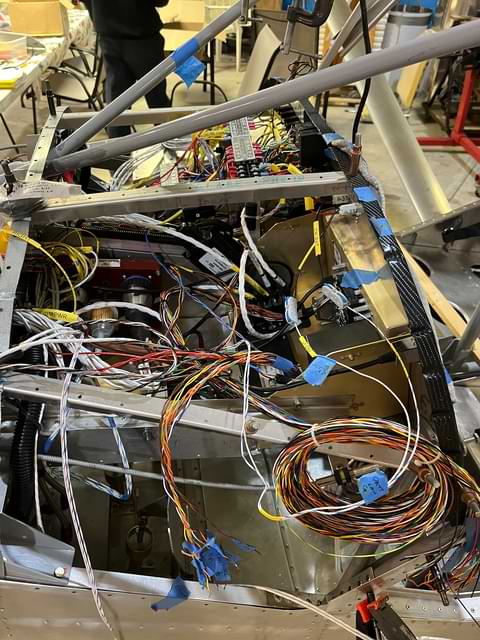

1.5 hr: Zee, Samuel 1 hr: Nolan, Ankith - Bolt eft flaperon sections together. Begin right side. - Study aileron motion limits (coming up short). Coupler is binding on its slot in the fuselage (the joys of CNC). - Continue routing aft wires under the seats to reach the panel. (Right side done.) 1565 hr cummulative

Roger at Zenith says the flaperon hinge pin is not structural. It's there to receive a washer and cotter pin (not shown on the drawings) to prevent the flaperon from moving laterally when grabbed at airshows. He recommends opening the hole in the horn and installing the washer. The right flaperon rubs the fuselage. Roger says they do bend the four hangers slightly outboard.

1 hr: Charlie, Ankith - On both sides, the fuselage flaperon hinge pin is not in alignment with those on the wing brackets. - Fabricate the other two antenna coax. 1562 hr cummulative

2 hr: Samuel, Zee, Trivid, Julian - Install all 4 flaperon segments. - Run GPS cable. - Grind out more holes below seat frame for passing through wires. - Remount alternator capacitor and master solenoid using nutplates for simpler access. 1560 hr cummulative

1 hr: Connor, Julian, Teyi - Run ELT's ground and RS-232 wires. - Finish last flaperon counterweight. - Begin fitting right wing flaperon sections. 1542 hr cummulative

0.5 hr: Julian, Samuel 1 hr: Charlie 2 hr: Zee, Teyi - Do another flaperon counterweight. - Trim and attach CHT and EGT wires to EMS. - Continue routing aft wiring to panel. 1539 hr cummulative

1 hr: Hope, Charlie, Killian, Paxson, Kagen, Zee 2 hr: Teyi, Ankith - Installed 2 of 4 flaperon counterweights. - Run flap motor wires to panel. - Run COM and transponder coax. - Begine running ADS-B coax. - Torque down all exhaust gaskets. 1533 hr cummulative

(There were no build sessions the previous two weeks.) 1.5 hr: Ankith, Paxson, Samuel, Soumik 2 hr: Connor - Finish installing pitot lines to ADAHRS. - Continue installation of throttle cables: Bulk head fittings at firewall, etc. Nearly done. - Begin routing aft wires under seats. Much more to do. - Purchase and fit runs of split, corrugated tubing for wiring runs in the footwell. 1523 hr cummulative

1.5 hr: Ankith, Teyi - Install pitot mast. Connect pitot and AoA to ADAHRS. - Install Outside Air Temperature probe and connect to ADAHRS. - Design and fashion a bracket to anchor the copilot's throttle to the map box. It was too flopsy. 1515 hr cummulative

1.5 hr: Hope, Julian, Paxson, Soumik, Abel, Samuel - Install 3D printed labels on electrical panel. - Fit outboard left flaperon. Inboard doesn't match the same trailing edge gap? - Study aft wiring route and decide to add conduit on cab sides in the foot well. - Begin dual throttle cable installation. 1512 hr cummulative

2 hr: Zee, Abel, Samuel, Soumik - Finish left and right wing struts and attach. Set airplane back on the ground. - Begin routing wires. Discuss location of buss bars. 1503 hr cummulative

1 hr: Samuel, Soumik, Hope, Paxson - Pracite drilling wing strut fittings. - Install left wing strut: Disassemble and deburr yet needed. 1495 hr cummulative

1 hr: Julian, Killian, Nolan, Samuel, Paxson, Charlie - While drilling, ruin left wing strut. Order new parts. - Test fit left wing wiring and pneumatic lines. - Plan wiring runs through center tunnel. Decide to run these on the belly of the plane. - Work on right wing upper strut fitting (try to avoid the mistake from the left wing). 1491 hr cummulative

1 hr: Julian, Killian, Trivid, Bobby, Abel - Install left wing strut. Not quite finished. 1485 hr cummulative

1.5 hr: Charlie, Bobby, Adrienne, Abel, Hope, Paxson - Mount to the firewall the main contactor and the big ULPower capacitor. - Mount both wings and re-measure angles in all three planes. - Drill and torque up all spar root bolts. - Drill right wing's strut fitting. - Bolt upper strut fittings to wing. - Trim struts to first pass length. 1480 hr cummulative

2 hr: Julian, Hope, Paxson - Remove wings to trim bottom skins for clearance with fuselage. - Re-route fuel lines in left wing root. - Add holes in left fuselage to accept wiring and pitot lines from left wing root. - Re-attach left wing and align. - Assemble battery box strap. Install battery. 1471 hr cummulative

1.5 hr: Soumik, Bobby, Julian - Mount and align both wings. (Aft spar bolts not yet drilled.) 1465 hr cummulative

1 hr: Trivid, Hope, Julian, Samuel - Discuss wing mounting sequence. Have scaffolds. Decide to order a 3/8 reamer for main carry through spar. - Install main battery. - Drill out temporary rivets on leading edge of wing root to access bolt holes. 1460 hr cummulative

1 hr: Paxson, Adrienne, Abel - Rearrange work space to allow wings to be fitted. - Measure all coax antenna runs. - Decide where to run all cables (10) through the center tunnel. 1456 hr cummulative

1.5 hr: Able, Adrianne, Paxson 0.5 hr: Trivid, Soumik - Begin routing engine bay wiring to behind panel. - Wire the elevator trim: Splice fuselage cable to elevator cable. - Secure the wiring cable for the belly strobe. - Finish both lower wing strut fittings. - Begin measuring antenna runs. 1453 hr cummulative

1 hr: Hope 1.5 hr: Paxson, Samuel, Abel, Julian, Trivid - Final tighten rudder cables. - Install belly strobe. Crimp wires to same. - Begin to assemble wing strut lower fittings. 1448 hr cummulative

1.0 hr: Charlie

2.0 hr: Hope, Samuel, Julian

- Modify rudder cable aft fairleads and fairings and install.

- Install both wing tip Nav/Strobe lights.

- Strip gap seals (due to poor sealant) from lower fin leading edge.

- Finish tensioning elevator cables.

- Measure cable lengths for Dynon data bus cables.

- Install Dynon HDX, COM-PANEL, and INTERCOM-2s in panel.

1440 hr cummulative

0.5 hr: Soumik, Paxson

1.5 hr: Hope, Able, Trivid, Bobby

- Begin final tension of elevator cables.

- Install GPS antenna on roof next to ADAHRS.

- Modify ADAHRS bracket so unit is better aligned with longitudinal axis.

- Fashion bracket for ELT and install ELT.

- Finish stiffener for avionics shelf. Bolt shelf down.

- Bend seat back so it can be installed backwards: "Headrest" frame is too low and too far forward.

1433 hr cummulative

2 hr: Trivid, Charlie - Finish riveting down the fin. - Reposition the gascolator to clear the steering gear. - Install stabilizer tips. - Fashion stiffener for the avionics shelf. 1426 hr cummulative

0.5 hr: Julian, Isaac, Paxson 2 hr: Hope, Samuel - Continue fastening the fin and rudder, nearly finished. - Continue working on the avionics shelf. - Install ADAHRS mount; forgot to drill the holes parallel to centerline, so redo next time. - Sand epoxy filler on wing tips. 1422 hr cummulative

1.5 hr: Zee, Paxson, Hope, Bobby, Samuel, Trivid, Nolan - Factory sent wrong part, so fashion and install new upper elevator stop. - Finish riveting down the baggage bay. - Make new bracket for ADAHRS, in upper baggage bay. - Continue filling gaps in plasitic wing tips. - Continue trying to fasten down the avionics shelf (slow going). 1417 hr cummulative

1 hr: Charlie, Julian, Killian 2 hr: Samuel, Paxson - Glue gap seals to fin and fin cover. - Change forward stabilizer bolts to accommodate an extra washer. - Begin to rivet in baggage bay including flaperon covers. - Install instrument panel back in cabin. - Install avionics tray between panel and firewall. - Fashion bracket to hold clear the elevator trim wiring. - First coat of epoxy filler for the gaps in both wing's tip panels. 1407 hr cummulative

1.5 hr: Charlie, Julian, Killian, Zee, Jude, Trivid - Add access plates in fin. Final torque the stabilizer bolts. - Rivet down the new upper elevator pulley brackets. Install upper elevator fairlead at fuselage. - Decide to glass over gap in wing tip sections, so install right and left wing tips. - Finish riveting the aft inner bulkhead. - Final torque and cotter pin the upper and lower elevator pulleys. Retension cables. - Start cutting supports for new elevator stop inside the controls tunnel. 1400 hr cummulative

1.5 hr: Hope, Samuel, Paxson - Fasten elevator counter weights. - Decide to raise upper elevator pulley to better clear stabilizer skin, so remove old assembly and begin to fashion new one. - Pull remaining rivets on right wing. Install aft wing tip, but forward wing tip doesn't fit? 1391 hr cummulative

1 hr: Paxson, Hope, Jude, Bobby, Julian, Zee - Remove fin and rudder. - Drill out rivets at the tail whose holes hadn't been properly deburred. - Back and forth on a redesign of the factory elevator stop. - Ditto for the upper elevator cable fairleads. - Rivet trailing edge of right wing back on. - Begin fitting wing tip to right wing. 1386 hr cummulative

1 hr: Samuel, Adrienne, Abel, Zee, Paxson, Hope, Charlie, Grady, Julian - Factory elevator stop is not satisfactory. Begin to lay out a new one inside the center console. - Clean out removed rivet heads from the wing. - Finish installing the upper strut fitting in the right wing. Close up that section of the wing. - Finish installing the new factory reinforcement at the root of the aft spar. 1380 hr cummulative

1 hr: Zee, Nolan, Grady 1.5 hr: Bobby, Julian, Able, Paxson - Remove rivets from right wing to access upper strut fitting, to install the strut fitting doubler which was left off. - Remove rivets from inboard trailing edge of right wing to install an aft spar doubler not shown on our kit's prints. - Finish both elevator cables. Finish left rudder cable, and begin right rudder cable. 1371 hr cummulative

1 hr: Abel, Adrienne, Paxson, Trivid, Samuel, Charlie - (Too windy to move the first wing inside for re-work.) - Cable swaging demo. - First elevator cable is done. - Change main battery strap to hinged from bolts. Discuss starter motor wiring. - Begin to rivet shut the tailcone skins. - Begin to file opening for the rudder cables at their fairleads. 1362 hr cummulative

2.5 hr: Paxson, Julian, Charlie - Fit left wing tip. Previous work not adequate. Will order new part. - Work on elevator cables. File elevator down stop. - Rudder cables are too long. Must fit new nicopress. - Landing light cover completed. - Cut round access holes in the covers for the flaperon rods to access bolts inside. 1356 hr cummulative

6 hr: Greg LePine - cover instrument panel with a plastic film 1349 hr cummulative

1.5 hr: Paxson, Grady, Bobby, Samuel, Trivid - Begin to fit the landing lights bezel. - Begin to fit the left wing tips. - Still trying to get control cables the correct length. 1343 hr cummulative

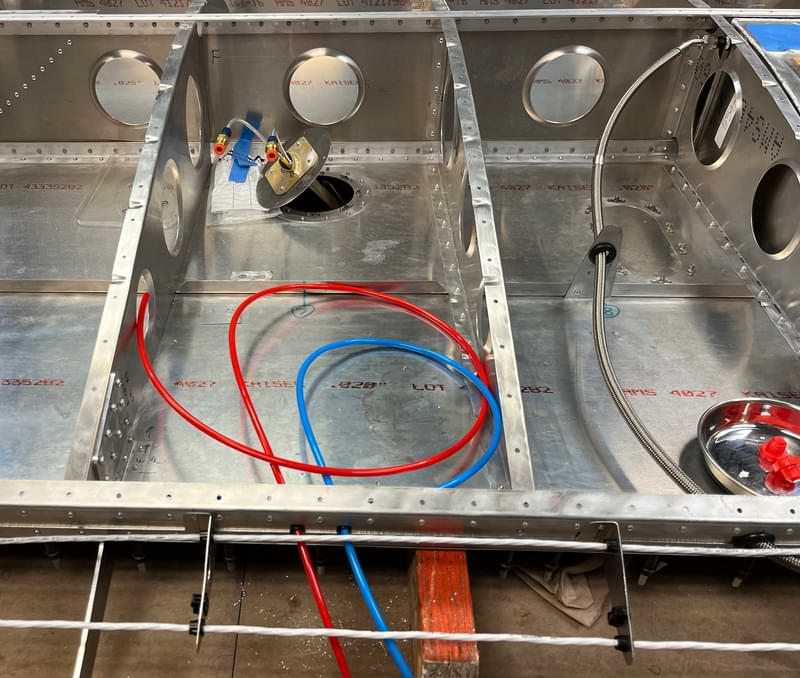

2.5 hr: Grady, Charlie, Trivid, Paxson - Start fitting and crimping elevator cables. Crimps poor, redo twice. - Run pitot and AoA lines to wing root under trailing edge. - Cut hole in skin over fuel tank for access to sender. - Set nutplates under top skin for cover over sender. - Drill screw holes in sender cover. - Finish drilling root leading edge skin. - Deburr trailing edge skins. - Cleco and rivet wing top skins. 1336 hr cummulative

1.5 hr: Julian, Paxson - Laid out panel holes for fuse and switch panels. - Rudder cables is too short. Pull it and start a new one. 1326 hr cummulative

2 hr: Samuel, Paxson, Charlie, Dominic - Attach fittings to pitot tubes. Run pitot lines to wing root. - Drill grommets for nav and landing light cables. Run cables to wing root. - Swaged rudder cables. Begin to open holes in sides of fuselage to clear rudder cables. - Fabricate brackets to hold ADAHRS. - Finish fuel lines in left wing. 1323 hr cummulative

2 hr: Julian, Charlie, Samuel, Abel - Experiment with mounting of pitot lines. - Start working fuel tank fittings and lines. - Rivet Dynon instrument tray to panel. - Rivet map box and various nutplates to panel. - Establish rudder throws by filing the stops. - Begin fitting rudder cable fairleads. 1315 hr cummulative

1.5 hr: Killian, Julian, Charlie, Dominic, Trivid, Paxson - Increase diameter of landing light brackets to receive the LED lamps. Install lamps, - Shim fuel tank into position with cork strips. - Build braces to tie map box to firewall. - Attach rudder stops to lower longerons. - Fashion and install brackets to hold fuel lines in the center console. - Deburr and rivet ELT antenna doubler and install antenna. 1307 hr cummulative

(There was no build session the previous week.) 1 hr: Grady, Samuel, Killian, Julian, Adrienne, Abel, Tyler - Finish trailing edge wiring brackets in wing. - Fashion, drill, and cleco ELT doubler plate to roof of baggage bay. - Run rudder cables from pedals aft. - Install fuel tank sensor and place cork strips on tank. - Attach aft tank support: Too far forward; must do it over. - Disassemble tail ahead of placing cables. 1298 hr cummulative

2 hr: Tyler, Grady, Charlie, Samuel, Trivid, Abel, Grace - Rivet on wing bottom skins. - Rivet on 3 of 4 flaperon brackets. - Change the trim motor wire bundle. - Construct the avionics tray. - Test re-routed fuel lines with air pressure, verifying fuel selector funtion. 1291 hr cummulative

2 hr: Killian, Bobby - Finish deburring wing skin. Rivet up landing light bracket. - Install wing trailing wiring support brackets. - Drill and tap Windshield side supports. 1277 hr cummulative

2 hr: Paxson, Trivid, Samuel. - Install COM antenna mounting plate. - Install Skybolt fasteners on lower engine cowl. 1273 hr cummulative

2 hr: Adrienne, Abel 1.5 hr: Bobby, Grady - Final deburr wing skins, ribs, and spars. A little more to do. - Final torque spar bolts to strut fittings. - Drill throttle to control panel. - Fashion struts to keep panel in position while glare shield is off. 1267 hr cummulative

2 hr: Julian, Charlie, Trivid, Tyler, Able, Adrienne - Install lateral stiffening ribs to wing top root skin. - Fashion bridge between leading edge skin and LE root skin. Fasten. - Finish ends of fuel lines. Attach to valve. - Cut outs in center console for new house route. - Attach hose covers at center console. 1260 hr cummulative

2 hr: Charlie, Julian, Paxson, Grady - Deburr bottom wing skin. Rivet on lateral stiffeners. - Fit wing root top skin and its angle. - Up drill landing light housing. - Trim top and bottom engine cowl. Begin to drill fastening holes. - Install forward bearing support for the control torque tube. 1248 hr cummulative

2 hr: Grady, Killian, Samuel, Abel, Adrienne, Trivid - Fit upper and lower cowl. Ready to drill. - Door frames are finished and ready for plexi. (Greg) - Finish drilling bottom skins. Reamer same. Finish fitting aileron brackets. - Remove bottom skins and begin to debuff. - Cut out landing light opening from leading edge skin. Deburr. 1239 hr cummulative

2 hr: Julian 1 hr: Samuel, Trivid (took Young Eagles flights) - Drill frame of landing lights to the leading edge skin. - Lay out the cut for the landing lights opening in the skin. Drill 4 corners. - Begin final assembly of controls torque tube. - Fashion covers for where fuel lines enter the center console from under the seats. 1227 hr cummulative

1 hr: Paxson, Killian, Samuel, Trivid, Bobby - Study door assembly. - Study landing lights assemblies. No conclusion. Not satisified with the factory kit. 1223 hr cummulative

1.5 hr: Paxson, Killian, Julian, Adrienne, Abel, Tyler, Trivid, Bobby - Discard factory's lower wing access panels. Install nutplates in the skins. Fashion new cover plates. - Install ADS-B-In and Transponder antennas. - Begin to install wiring run brackets on the aft spar. - Trim lower cowl around the nose inlets. 1218 hr cummulative

1.5 hr: Paxson, Julian, Samuel, Trivid, Tyler - Finish installation of pitot mast. - Finish drilling remaining aileron brackets. - Final (?) rerouting of fuel lines to center console: Had to go under seats. - Finish making aft wing spar brackets to hold sundry lines. 1206 hr cummulative

2 hr: Killian, Eli, Samuel 1.5 hr: Paxson, Julian, Nolan, Collin - Study poor fit of engine cowl around engine. Is the engine mount correct? Will call Zenith. - Layout mounting plate for COM antenna. Will coax hit the fuel lines? - Elevator push-pull rod is hitting fuel lines. Identify alternate routing of lines. May affect COM antenna. - Cut wing skin for pitot mast mounting plate. Begin to drill same. - Fabricate more wiring brackets for inside of trailing edge of wing. - Review and test assembly of door frames. Rivet gun will not fit correctly inside acute angles? 1198 hr cummulative

1.5 hr: Paxson, Collin, Samuel (new) - Make try spacer for spinner to cowl. Adjust baffles to cowl. Cut/repeat. - Work on layout of antennas. - Install cover plate for access hole on trailing edge of wing. 1188 hr cummulative

2.5 hr: Luke, Killian, Collin, Adrienne, Abel, Paxson - Install fuel sender. - Begin fabricating brackets for the wing's trailing edge wiring. - Begin laying out installation of the pitot tube mast. - Prepare an access panel over the aft inboard edge of the fuel tank. - Torque prop spinner in place. Study fit of the cowling, finding several concerns, may have to add a blister. 1184 hr cummulative

2 hr: Paxson - Add sealant around fuel line grommets. - Resume work on the engine cowl. Realign oil cooler to the cowl. 1169 hr cummulative

1.5 hr: Julian, Zee, Wyatt, Bobby, Grace, Ishan, Paxson, Numit, Collin - Install EGT probes. - Trim down and install cylinder internal cowls. - Start to install flaperon brackets. - Fit spacers for fuel tank in its bay. - Start layout of HDX display in panel. - Rivet door hinges to canopy frame. View installation videos. - (Two new builders to be shown the ropes. Good-bye to Ishan.) 1167 hr cummulative

2 hr: Ishan, Killian, Grace, Julian, Bobby - Add grommets to fuel lines at the bulkheads in the control tunnel. - Install CHT probes. Verify EGT probe fits; need 3 more. - Add weatherstrip to fin. - Study the installation of the landing lights: not ideal. - Begin installation of fuel tank sender and plumbing. Cut holes into tank. 1153 hr cummulative

2 hr: Abel, Paxson, Ishan, Bobby - Ream to size the rivet holes on the top side of the wing. - Start to study the landing lights mount. - Updrill rivets on fin to final size. Deburr. - Fit rubber trim between fin and stabilizer. Need to order taller trim. - Re-route fuel lines in the control tunnel in order to clear controls. 1143 hr cummulative

1.5 hr: Killian, Paxson, Bobby 2 hr: Grace, Luke, Adrienne, Abel, Nolan, Zee - Fit and drill wing top skins. - Finish fitting and drilling brackets for the fin. Need to upsize rivet holes yet. - Finish placing last door sill frames and begin to assemble the doors. 1135 hr cummulative

1.5 hr: Adrienne, Abel 2 hr: Paxson, Zee, Wyatt, Bobby, Luke, Grace - Brackets for fin fairing riveted down. - Continue fitting front door sills. - Fit the top skins; short on clecos. - Install all the cabin's fuel line fittings, with sealant. 1119 hr cummulative

2 hr: Bobby, Karl - Finish reaming rivet holes to correct size. - Fit root leading edge skin. - Locate and place skin stiffeners between ribs. 1104 hr cummulative

1.5 hr: Paxson - More fuel lines work. 1100 hr cummulative

3 hr: Ishan 1 hr: Karl - Continue assembling and installing fuel lines. - Finish drilling bottom skins to spar cap. - Finish drilling strut fitting supports. - Begin to ream wing skin to rib holes (these are undersize). 1098 hr cummulative

3 hr: Ishan 2 hr: Grace, Adrienne, Killian, Bobby, Luke - Assemble and route fuel lines. Start cutting hold downs for lines. - Drill up fin to elevator rivet holes. - Fit L brackets for fin fairing. - Begin drilling lower wing skins to spar and ribs. - Reverse direction of bolts hold front fork in place—too close to tire. 1094 hr cummulative

1.5 hr: Ishan, Karl - Mounted gascalator and fuel return line's bulkhead fitting. - Consult with factory. Decide to replace two aft spar rivets with bolts per latest specs. - Locate pitot assembly and consult with on-line data sheet for same. - Discover extra A6 rivets and finish riveting up the spar's tip extension. 1081 hr cummulative

3 hr: Karl - Finish deburring, reaming, and riveting the wing skeleton. 1078 hr cummulative

1.5 hr: Ishan, Karl - Deburr wing parts, begin to reamer the tight holes. - Mounted battery box and heater box; cut hole for ECU cables in top left fire wall. 1075 hr cummulative

1.5 hr: Killian, Ishan, Julian, Bobby - Bracket from stabilizer to fin is riveted. - Fit fin lower skin. Mock up bracket between lower fin skin and fuselage. - Up drill wing ribs and begin to deburr. - Notice two pieces from right wing that hadn't been installed. These will be installed later when the tips are being done. - Decide to reverse bolts on front wheel fork--not finished. - Planning on the panel layout. - Planning for fuel line runs. 1072 hr cummulative

2.5 hr: Grace, Julian 1 hr: Bobby - Fasten fittings to fuel selector. Attach selector to center console. - Fit spinner and prop hub to engine. - Begin test fitting engine cowls. - Drill and cleco to the stabilizer skin the brackets for the fin skin. - Remove metal from skin of fin to match stabilzer contour. - Match drill all ribs to the main spar in the left wing skeleton. 1066 hr cummulative

2.5 hr: Adrienne, Able, Bobby, Paxson, Ishan, Julian 1.5 hr: Grace - Mount fuel selector to the center console. - Finish spark plug wires. - Up-drill and assemble aft spar to wing skeleton. - Fiddle with windscreen fit. Much windscreen will have to be trimmed away; it appears to be cut for the Un-Panel. - Fit angles inside the fin to connect it to the stabilizer. - Make spacer for the front right stabilizer bolt. - Fashion new brackets for those missing in the elevator. Discuss how to rivet them down. 1060 hr cummulative

1.5 hr: Paxson, Julian, Bobby, Zee, Ishan - Attach upper elevator pulley. - Practice peen forming the fin attach angles. - Continue assembling the left wing skeleton. - Have to correct factory holes in aft wing spar. - Rearrange the spark plug wires to have less overlap. - Discover missing bracket in the elevator; identify the fix. 1044 hr cummulative

1.5 hr: Killian, Paxson, Ishan, Wyatt, Zee, Luke, Bobby - Fabricate and install spark plug wires. - Install cooling blast tube to ignition module. - Move nearly completed right wing to end cap for storage. - Fetch and deburr the parts for the left wing skelton. Begin to assemble. - Drill and bolt stabilizer to fuselage. 1036 hr cummulative

2.5 hr: Paxson, Able, Adrienne, Julian 1.5 hr: Nolan, Grace, Killian - Install the shorter spark plugs wires. Align oil cooler with lines. - Discuss ECU location. - Finish riveting the right wing shut. Work on the wing tips. - Align the tailplane and pilot drill the two front bolt holes. - Finish drilling and rivet down the bottom and aft door sills. 1025 hr cummulative

2 hr: Able, Paxson, Nolan - Begin to rivet top wing skin. - Study how to assemble ignition wires and locations. - Discuss ECU location. - Install lines to oil cooler. 1011 hr cummulative

1.5 hr: Grace, Adrienne, Abel, Killian, Paxson, Ishan, Julian - Continue drilling door sills. - Install cover for fuel sender (sheet metal screws). RTV sender wires down. Final inspection: ready to close! - Rivet down upper and lower aft fuselage skins. - Install rear tie down. File down rough cast hook. - Fasten down lower elevator pulley. - Install oil cooler and lines; wrong fitting shipped with kit. - Install oil separator line. 1005 hr cummulative

2 hr: Killian, Wyatt, Zee, Julian 1 hr: Paxson, Ishan, Bobby - Install muffler and heat muff. Run tubing from upper cooling plenum to heat muff. - Attach oil cooler mounts. - Finally decide on location of fuel selector and fuel line runs. - Test fit fin. The bottom of it skin will have to be worked down to fit over the tailplane. - Fashion lateral reinforcing angles for both elevator pairs of pulley brackets. - Finish wiring and plumbing runs in right wing. - Continue drilling door sills. 995 hr cummulative

2.5 hr: Wyatt, Zee, Ishan - Install oil cooler bypass thermostat. - Remove exhaust pipes and install new crush gaskets. - Install elevator balance weights. - Fashion a new, angled bracket for the top elevator pulley, to increase clearance at cables crossing point. 984 hr cummulative

2 hr: Zee, Wyatt, Paxson, Killian, Bobby

- Work on engine baffling.

- Work on positioning the elevator pulleys aft: Close fit; may have to build custom brackets.

- Finish wiring the wing; work on the fuel lines; nearly ready to close the wing.

- Continue positioning and drilling the door sills and striker plates.

977 hr cummulative

2 hr: Killian, Julian, Ishan, Bobby - Install left coil, voltage regulator, and cylinder baffles. - Discuss panel layout and wiring further. - Rivet aft spar together. Continue tying down wiring runs. - Position and begin to orient tailplane. Will need to make shims. 967 hr cummulative

2 hr: Killian, Paxson, Julian, Ishan, Bobby - Install more trailing edge brackets for electrical and fuel lines. - Install FWF fuel lines. Replace factory line with fire sleeved line. - Install left and right mounting panels to the engine mounts. - Install right ignition coil to its mounting panel. - Start fitting right door sill. - Finish installing nutplates in the center console. - Discuss panel and avionics layout. 959 hr cummulative

1.5 hr: Bobby, Paxson, Killian, Nolan, Ishan - Install nut plates along top of controls tunnel. - Install last stage fuel filter to engine mount. - Install left side mounting plate to engine mount. - Sketch layout of the instrument panel. 949 hr cummulative

1 hr: Wyatt, Zee, Paxson, Ishan, Nolan, Bobby, Killian - Mount engine (s/n 233502) to airframe. Reverse orientation of fuselage to have room to mount tail planes. - Drill and rivet top door sills. - (slow day; few mentors) 941 hr cummulative

2 hr: Grace, Julian, Bobby - Install nose wheel and axle. - Sketch out the layout of the firewall components. - Refine the routing of the nav lights and magnetometer cables. Make additional brackets and install Adel clamps. - Nearly finish installing the brake lines. 934 hr cummulative

2 hr: Julian, Killian, Paxson, Grace, Adrienne, Ishan

- Drill center console side sheets for nutplates. Need to order special plates.

- Fit engine mount to engine and set compression of the rubber bushings.

- Deburr, fit, and start to pilot drill the top door sills to the cabin frame.

- Rivet seat bases into place.

- Rivet flaperon brackets in place.

- Set steering rods to correct length. Place nose wheel: must replace missing washers.

928 hr cummulative

1.5 hr: Adrienne, Abel, Bobby, Julian 2 hr: Paxson - Drill baggage floor to seat pans. - Begin to rivet seat pans. - Clean up bearing blocks to rudder pedals. Lube & bolt down. - Clean up bearing block on nose gear. Lube & bolt down. - Pull engine from box and begin to fit the engine mount. - Start to assemble fuel filters to their mount; missing parts. - Make more brackets for rounting electrical and fuel lines in right wing. 916 hr cummulative

1.5 hr: Paxson, Grace, Ishan, Nolan - Rework flaperon bracket supports. - Add extra spacers for fuel tank. - Install nose gear; a little tight yet. - Fit fuel pump's bracket to firewall. - Center console will need nutplates. Fiddle with placement of the nutplates. 908 hr cummulative

3 hr: Karl - Slot in forward top sheet is not centered; widen it to fit the steel tubes which pass through. - Heel Support Gussets had been left out when the Forward Angles had been riveted in yesterday. Remove rivets and re-install. 902 hr cummulative

1 hr: Paxson, Killian, Julian, Wyatt, Zee, Ishan - Fasten lower engine brackets to longerons. - Rivet steel cabin framing to the airframe. - Rivet firewall and forward cabin framing together. - Bolt down the lower nose gear bracket. - Fasten down parking brake valve. - Watch engine installation video; mentor for the wing assembly couldn't attend. 899 hr cummulative

3 hr: Ishan 4 hr: Beth - Match drill new forward top sheet to old one. - Attach forward top sheet. Fashion and attach stiffening ribs. - Drill forward top sheet to upper cabin longerons. 893 hr cummulative

2 hr: Julian, Ishan 3 hr: Beth - Reassemble right brake. - Finish constructing and install center console with clecos. - Cotterpin the bolts next to firewall (brake pedals). Insert firewall again. - Install new instrument panel, drill and cleco (in the correct location this time). 886 hr cummulative

3 hr: Beth - Final torque upper mount brackets. - Prepare countersunk screws at front of lower mount brackets. - Deburr firewall. 879 hr cummulative

1 hr: Beth - Drill top two bolts for engine mount at firewall. 876 hr cummulative

1 hr: Adrienne 2 hr: Paxson, Killian, Julian - Prepare and finish left wing root access panel. - Start left wing fuel sending unit fairing. - First routing of brake lines. - Second main wheel mounted. - Mount main gear to fuselage. - The left side calipers are binding; take off wheel to investigate. - Bolt engine mount brackets to longerons. - Drill engine mount bolt holes through firewall and into brackets. Test fit mount. 875 hr cummulative

0.5 hr: Wyatt, Zee - Construct mounting bracket for the parking brake valve. 868 hr cummulative

2.5 hr: Ishan, Beth - Finish drilling the cabin forward top skin to instrument panel. - Form and drill the two right side ribs for the top skin. 867 hr cummulative

2 hr: Killian 3 hr: Ishan - Brake pedal hinge was riveted with the wrong rivets. Drill out and replace with stainless. - Remove firewall and cabin sides to deburr; reassemble with top skin to firewall. - Much squirming of the firewall top skin, then finally begin drilling into firewall. 862 hr cummulative

2 hr: Paxson, Julian, Killian, Ishan - Cut rib for return fuel line. - Cut wing root access panel in the skin. - Assemble shock pucks on to front gear. - Finish drilling engine mount brackets. Must move a hole back, for it's too close to the end. - Thread and fasten lower plastic blocks for front gear. 857 hr cummulative

1.5 hr: Killian, Grace, Adrienne, Julian, Wyatt, Zee, Paxson - Begin drilling engine mount brackets. - Begin work on assembling shock nose gear. - Installing fittings on the fuel tank. - Run magnetometer wires. - Finish wheels and brakes on one side of mains. Strip cap screw head on other side: Order replacement. - Check rudder cable runs with a string. 849 hr cummulative

1 hr: Grace

2 hr: Julian, Paxson, Ishan, Killian

- Assemble main wheels and brakes onto spring gear.

- Misaligned rivet holes attaching inner seat belt bracket to main gear channel, so enlarge holes and rivet with next larger rivets.

- Drill more 1/2" passage holes in rear seat channel (F11-3) for wiring and plumbing (factory gives only 6).

- Finish fitting brake pedals to rudder pedals. Test fit brake cylinders and steering rods.

- Right wing: Run fuel hoses and strobe and magnetometer wires. Add hole for fuel return line.

- Install fuel gauge sending unit.

839 hr cummulative

1.5 hr: Adrienne, Abel

2.0 hr: Nolan, Paxson, Ishan, Able, Julian, Killian

- fashion and attach brackets for aft spar to hold wiring and fuel line runs

- drill and cleco instrument panel to the steel tube on which it rests

- assemble center console

- fashion main landing gear brackets,

- begin assembling rudder pedals and their hinges

830 hr cummulative

1 hr: Nolan 1.5 hr: Ishan, Paxson, Killian, Julian, Grace, Wyatt, Zee - Brackets for wiring on trailing edge aft wing spar. - Verify all wing parts are in place. - Torque down strut attachment bolts to wing spar. - Start fitting the center console. Have to drill out rivets from bottom skin. - Notch & polish main landing gear: Ready to prime & mount. - Mount fuel sender bracket to the tank. Lay out inspection hole for same in the top skin. Flush tank. Begin fitting wiring to fuel sender. - Mark the top brackets for the top longeron to firewall mount. 815 hr cummulative

1.5 hr: Grace, Wyatt, Zee, Killian, Ishan, Paxson - Rivet inter-rib stiffeners to bottom of wing top skin. - Drill out and re-rivet the reinforcing plate for the magnetometer (bottom wing skin). - Fashion the last forward channel for the cabin sides. - Finish riveting the bottom skin of the cabin. - Start riveting the seat base structure to the cabin sides. - Continue work on fuel tank installation. - Begin drilling the engine mount brackets to the forward longerons. 803 hr cummulative

2.5 hr: Wyatt, Zee, Ishan 1.5 hr: Killian, Grace, Adrienne, Abel - One cabin forward channel isn't right and will be replaced. - Almost finish the riveting of the cabin belly. - Begin fitting engine mount to firewall. - Begin fitting cabin's engine mount brackets, and prepare shims for lower pair. - Finish bolting the wing strut bracket to the lower longerons (tight fit for the nuts). - Work on mounting magnetometer plate; rivets are loose and must be drilled out. - Finish fitting fuel tank to wing, and begin fitting fuel sender to the tank. 794 hr cummulative

2.5 hr: Wyatt, Zee 2.0 hr: Ishan 1.5 hr: Eli - Deburring wing ribs. Begin fitting the wing tank. - Almost finish forming and fitting the forward channel assemblies. - Deburr instrument panel and forward top skin. - Resume riveting of the cabin belly skins. 780 hr cummulative

2 hr: Luke, Killian, Paxson, Ishan, Wyatt, Zee, Adrienne, Abel, Grace - Deburr upper wing skin. Root wing skin needs a few extra rivets to repair ovaled rivet holes. - Continue making and attaching forward channel assemblies, both sides. - Work on fastening C4-8 to the belly. This should have been done earlier in the assembly! May have to use bolts. - Inventory all parts which came in the crate with the UL Power engine (received this week from Belgium). 772 hr cummulative

1.0 hr: Killian

1.5 hr: Adrienne

2.0 hr: Nolan

2.5 hr: Paxson, Ishan

- Finish new elevator bell crank framing.

- Test cables to elevator aft pulleys: We have clearance where the cables cross mid fuselage.

- Back drill firewall to cabin sides.

- Continue fitting forward channel assemblies to the sides of the cabin near the firewall.

754 hr cummulative

0.5 hr: Eli 1.0 hr: Wyatt, Zee, Killian 1.5 hr: Nolan, Adrienne 2.0 hr: Paxson, Ishan - Mount magnetometer in bottom wing skin. - Install and begin to rivet in place the new elevator bell crank assembly framework. - Rivet down belly skin, etc under right seat. - Begin to form the forward channels on the sides of the cabin aft of the firewall. 745 hr cummulative

(The builders worked at the benefit for the LifeLine Pilots.)

(Too many mentors happened to be out of town, and this session was canceled.)

1.0 hr: Adrian, Eli (in training) 1.5 hr: Killian, Julian, Paxson 2.5 hr: Nolan - Layout and drill up Front Cabin Frame Gussets. - Continue cutting and fitting ABS wing tips. - Drill and cleco the lateral stiffeners for the wing root skin. - Start to re-install baggage bay sheets ahead of fitting new elevator bell crank supports. 733 hr cummulative

2.5 hr: Nolan, Ishan 2.0 hr: Paxson 1.5 hr: Killian 0.5 hr: Eli - Rivet down the front cabin floor. - Attach and drill the cabin's steel cage. - Begin cutting out the ABS wing tips. - Drill last holes in wing root skin and form its lateral stiffeners. 724 hr cummulative

1.5 hr: Wyatt, Zee, Julian, Paxson, Isaac, Ishan 0.5 hr: Adrian (new) - Low productivity day. - Pilot holes in upper wing root skin from factory are out of place. Move holes. - Wing root angle (W6-5) is too short. Make an extension and fit it. - Beging fitting and drilling the torque tube end plate mounting. - Finish up drilling and deburring bolt and rivets holes in cabin floor near the pedals. Ready to rivet. - Brake cylinder brackets were to be riveted, but we now have (overkill) bolt holes. 715 hr cummulative

0.5 hr: Killian 1.0 hr: Ethan 1.5 hr: Julian, Alex, Eli 2.0 hr: Ishan, Wyatt, Zee, Luke - Updrill top skins of right wing. Begin fitting wing root assembly. - Match drill bottom longeron to cabin floor in front; use files to better align holes before finish drilling. Mistakenly drill out a bolt hole, so add another bolt hole to rudder pedals floor bracket. - Test fit new brackets to hold elevator bell crank in proper position. - Work on bracket which holds aft end of stick controls torque tube. This is in an awkard location. 706 hr cummulative

2 hr: Grace, Paxson, Wyatt, Zee, Ishan, Nolan, Luke 1 hr: Julian, Eli - Begin to fit top skin of right wing. Not enough clamp straps. - Fabricate, fit, and install the angles between the gear channel and the cabin sides. - Fit bases of the wing nav lights to the plastic tip pieces. - Begin to fabricate an access cover which will carry the magnetometer. - Study new Cruzer drawings to compare the changes to the elevator cables problem to the fix we have begun. 692 hr cummulative

2 hr: Grace, Killian, Ishan, Luke - Double check deburring and then rivet bottom skins to first wing. - Discuss systems which must be mounted inside this, the right wing: Wing tip strobe, magnetometer, fuel tank and lines. 676 hr cummulative

2 hr: Luke, Isaac, Zee, Wyatt - Deburr lower wing skins, spar, ribs, and stiffeners. Nearly ready to rivet. 668 hr cummulative

2 hr: Julian, Nolan, Isaac, Wyatt, Zee, Paxson, Killian, Ishan - Wing drilling and deburring. - Scratch head over joint between gear channel and cabin sides. Will need to make a custom piece. 660 hr cummulative

2 hr: Zee, Paxson, Ishan, Grace, Isaac 1.5 hr: Nolan, Ethan - Finish torquing bolts around landing gear channel. Rivet cabin sides and gear channel to aft fuselage. - Disassemble wing to begin deburring. Demo on flush mounting nut plates. Install first plate. - Study cabin drawings and guide. 644 hr cummulative

5 hr: Karl and (young) Karl - Remove gear channel to replace the inboard rivet of the doublers with a bolt, per the drawing. - Torque down bolts to the steel brackets at the ends of the gear channel. - Begin to rivet cabin sides to the aft fuselage. 631 hr cummulative

2 hr: Wyatt, Zee, Killian, Grace, Ishan - Continue wing assembly, bottom skin and fittings. - Fit bolts to steel bracket tying wing strut to lower longerons. 626 hr cummulative

2 hr: Ishan, Luke, Wyatt, Zee, Nolan - Continue skinning the first wing. - Study fit of control linkages in the cabin. - Review antenna mounting locations. 616 hr cummulative

2.5 hr: Julian, Killian, Zee, Wyatt, Paxson, Isaac - cabin deburring and reassembly - wing skins 606 hr cummulative

4 hr: Karl - drill and rivet gear channel doublers - install cabin sides and floor ahead of deburring 591 hr cummulative

2 hr: Killian, Paxson, Grace, Wyatt, Zee, Luke - reassemble and rivet wing skeleton - layout and drill last row of rivets for the seat pans - disassemble cabin floor and remove cabin sides to deburr bolt holes to landing gear bracket 587 hr cummulative

1 hr: Paxson, Luke - deburring wing parts 575 hr cummulative

2.5 hr: Grace, Isaac, Julian, Luke, Paxson, Ishan

2 hr: Nolan

- assemble wing skeleton

- assemble landing light bracket

573 hr cummulative

2.5 hr: Ishan, Paxson - assemble wing skeleton 556 hr cummulative

2 hr: Killian, Ishan, Julian, Paxson 1 hr: Nolan - Rivet up the two remaining flaperon sections. - Gather parts for right wing's skeleton. - Drill out first of four strap doublers between the steel bracket and the main gear channel. 551 hr cummulative

2 hr: Killian, Julian, Alex, Wyatt, Zee, Ishan - Assemble remaining 3 flaperon sections and and rivet up one of them. - Drill right landing gear brackets to fuselage. - Inventory parts from Stein, Aircraft Specialty, and Zenith. 542 hr cummulative

2 hr: Killian, Paxson, Julian, Wyatt, Zee, Ishan, Alex - Assemble remaining 3 flaperon sections. Don't have the narrow nose riveter, so stop at clecos. - Drill holes in nose wheel fork for the axle. Slightly undersize. Fiddle with adjustable reamer to fix hole. - Continue work on seat support framing in the cabin: Getting close. 530 hr cummulative

2 hr: Ishan, Isaac, Paxson - Rivet up first flaperon section. - Begin next flaperon section. 516 hr cummulative

2 hr: Grace, Ishan, Paxson, Killian - Begin drilling the steel strut attach bracket to the longerons. - Begin riveting first flaperon assembly together. Wrong riverter head used, so drill out all the rivets. 510 hr cummulative

1.5 hr: Julian, Killian, Zee, Paxson, Luke, Ishan - Start assembly of first flaperon. - Continue cabin assembly. - Continue discussion on what must be mounted inside the wings before those can be closed. 502 hr cummulative

It was agreed no antennas are needed in or on the wings. This started another discussion.

1.5 hr: Killian, Paxson, Grace, Wyatt, Zee, Ishan, Julian - Continue seat support fixes. - Flaperon deburring. - Discuss plumbing and wiring which will be needed inside the wing being assembled. 493 hr cummulative

Rob Meyer talked about the fuel system requirements for the UL Power engine selected for this project. After a discussion, the following decisions were made:

2.5 hr: Wyatt, Zee, Grace, Killian, Julian - Remove from tailer and inventory most of the wing kits. - Rearrange stacks in the hangar, and then move the fuselage to sawhorses in the space freed. - Resume work on the seat support brackets. - Begin assembly of the flaperon. 484 hr cummulative

1 hr: Paxson, Ishan, Nolan - Fuss with fitting the angle attachments for the seat base to the cabin sides. - Fuss with the fit of the steel main gear brackets to the airframe. - Frustrating morning over all with little to show for it. Fortunately, the wing kit arrives this coming week. 472 hr cummulative

1.5 hr: Zee, Wyatt, Nolan, Killian, Ishan, Paxson - (It was difficult to keep all 6 teens busy this week.) - Finish etching the fuselage sides and top. - Work on the angle brackets for the seat supports. (Argh.) - Build up nose gear fork and strut: Drill and bolt. (Photo guide calls for AN4 but prints call for AN3.) 469 hr cummulative

It was found other builders assemble the cabin separately on a table, and the factory's assembly photo guide does this. The teens chose to do so, but this, compounded with errors in the factory drawing, has created a problem. The Rear Seat Channel mates to the main Gear Channel. In our kit, the supplied rivet holes on the Gear Channel were about 4 mm too far forward. Worse, in laying out the rivet and bolt holes in the Seat Base per drawing SSO-1, this resulted in the both the Front and Rear Seat Supports being forward. In turn, the Rear Seat Support can not attach to the cabin side member indicated in SSO-1. Extra L angle attachments must be fabricated, but because the holes in the Seat Base were drilled before its Seat Supports were fitted, and because these holes locate the Seat Supports, it's quite a pill to reach the location where the angle attachments are to go. In hindsight, an alternate assembly sequence would have been better. Attach with clecos the cabin sides to the aft fuselage. Attach the floor and its various longitudinal and lateral stiffeners. Attach the Seat Channel and Arm Rest Sides to the floor and to each other. Attach the Seat Bases to the Seat Channel and the Rear Seat Channels. The latter should be in their correct position against the aft fuselage's Side Channel (C75F4-1) to which they will eventually be riveted. Prepare new rivet holes up through the Gear Channel into the Rear Seat Channel and rivet. Add the angle attachments to the front of the Seat Channel. Remove the Seat Base and position the Rear Seat Support per the drawings. Drill and cleco the Rear Seat Support's end to the extrusion in the cabin sides, and then make the angle attachments between the Arm Rest Sides and the Rear Seat Support; drill and attach. Position the Front Seat Support 275 or 280 mm forward of the Rear Seat Support and do the angle attachments. (The drawing in SSO-1 shows a spacing of 275 for the bolt holes in the seat slider rails, but ours measured 280.) Replace the Seat Base and layout the rivet holes for both the top and bottom flanges of the Seat Support channels. Be sure the bolt hole pattern for the seat sliders is square.

2 hr: Grace, Wyatt, Zee, Killian, Ishan, Alex - Scotch Brite the rudder and fin for (later) painting. Start same on fuselage. - Drill brake cylinder mounts to cabin floor. - Begin to assemble cabin onto the aft fuselage. Seat bases don't align with cabin sides, so will have to fashion extra brackets. 460 hr cummulative

2.5 hr: Julian, Ishan 4 hr: Killian - Since the plane will most likely be painted, work began to Scotch-Brite the aluminum surface. - Drill up several rows of punched holes in the cabin floor from #40 to #20. - Drill bolts holes for the rudder pedal brackets. Layout brake cylinder mounting brackets. - Discover the seat base assemblies are crooked, and begin drilling them out for rework. 448 hr cummulative

1.5 hr: Killian, Paxson, Ishan, Wyatt, Zee, Nolan, Isaac, Julian - Fiddle with new elevator bell crank layout and linkage. - Begin fitting main wheels to main gear. Fit could be better. One set of brake pads binds on its ways. - Work on attaching rudder pedal assemblies to cabin floor. Factory holes are too tight a fit. - Start fitting the bearings for the control stick's torque tube. 439 hr cummulative

1.25 hr: Grace, Julian, Isaac, Nolan, Wyatt, Zee, Paxson, Killian 0 hr: Ishthan (learning deburring, etc) - Limited number of parts to work on today, so a bit slow. - Continue assembly of cabin floor. - Begin fitting rudder pedals to floor. - Figure out how to trim rubber shock bushing for the main gear. - Continue fitting parts for new elevator bellcrank. Craig Hittle fashions new parts for control linkage. - Deburr center console parts. - Deburr wing struts, but can't add fittings until final assembly. 427 hr cummulative

3 hr: Karl, Jim - Trial and error fitting of cabin sides into slots in aft fuselage. 417 hr cummulative

1 hr: Will 2.5 hr: Alex, Paxson, Killian, Grace, Wyatt, Zee 3 hr: Julian - Finish assembly of fire wall. - Finish fitting of the seat supports. - Finish assembly of sliding seat and frames. - Rivet most of the aft fuselage together. Includes fix of top channel deburring mistakes. - Disassemble cabin and begin to reassemble onto aft fuselage. Begin fitting main gear support structure. 411 hr cummulative

1.5 hr: Killian, Alex, Julian, Grace, Paxson, Wyatt, Zee - Brackets fashioned and installed on the seat supports. - Riveting of the fuselage continued. - The new top channel was match drilled to the top skin using a tool Dean Lake had machined to accurately center the drilling. Mistakes in deburring will require some of the holes to be drilled up for 3/16 rivets. 392 hr cummulative

2 hr: Paxson, Nolan, Wyatt, Zee, Will, Killian - Rivet up rear carry through spar. - Begin riveting seat supports. - Deburr firewall and begin riveting. 381 hr cummulative

1.5 hr: Grace, Nolan, Zee, Wyatt, Paxson, Killian, Julian, Alex - Seat assembly: got ahead of ourselves and will have to drill out rivets. - Front tire assembled. - Begin fitting new top channel assembly. - Discussion on wiring runs in the fuselage assembly sequence. 369 hr cummulative

1 hr: Paxson, Julian, Killian - Firewall match drilling and some riveting. 357 hr cummulative

1.5 hr: Paxson, Killian, Nolan, Isaac, Will, Alex - Long discussion on placement of antennas, ELT, bungee on the elevator cables, etc, before closing the fuselage. - Start to rivet up the sides of the fuselage. - Work on fittings on the firewall. - Strip powder coat from the nose gear strut where the rubber shock biscuits are to slide. - Further assembly of the control linkages. - Andy and Jim looked at the fit of the rear carry through spar and agree with Karl that new pieces are required. 354 hr cummulative

1.5 hr: Paxson, Grace, Julian, Nolan, Isaac, Zee, Wyatt, Killian - Rear carry through spar (top channel) rivet holes don't match skin. New parts are being prepared by the factory. Aft fuselage assembly is halted. - Both main gear wheels/tires assembled. - Begin fitting firewall together. - Inventory the firewall forward kit (no missing parts). - Test nose gear shock parts: Will have to remove some of the powder coating. - Fit some of the flaperon linkages. Some parts were difficult to locate in storage. 345 hr cummulative

2 hr: Wyatt, Zee, Grace, Will, Paxson, Killian, Julian - Prepare to rivet fuselage; ream tight holes; place pull rivets. - Reassemble baggage bay to assure it remains in alignment while riveting the rest. - Assemble rear carry through spar. Parts don't fit correctly. - Continue working on the seat support structure. - Begin assembly of main gear wheel and tire. 333 hr cummulative

3 hr: Grace 1.5 hr: Luke, Nolan - Steady progress on the seat framing by Grace. - Defective parts in the wheel assemblies and the rear carry through spar hindered progress by Nolan and Luke. 319 hr cummulative

2 hr: Will, Paxson, Zee, Grace, Wyatt, Julian, Killian - Test trim tab motor. Finish riveting the elevator/stabilizer assembly together. - Continue fitting seat pans to their supporting structure and building up the underlying structure. 313 hr cummulative

2.5 hr: Isaac, Paxson 1.5 hr: Will, Julian 0 hr: Grace (finished training) - Begin riveting elevator/stabilizer assembly. - Assemble both seat pans. Begin to drill and cleco their supports to the cabin floor. 299 hr cummulative

2 hr: Nolan, Isaac, Paxson 0 hr: Julian, Grace (both in training) - Finish wiring inside elevator, etc. - Install seat pans and their braces in the cabin. 291 hr cummulative

2 hr: Isaac, Nolan, Paxson, Luke, Killian - Drill elevator to hinge, disassmble, deburr, begin to reassemble. - Begin to assemble cabin section of the fuselage. 285 hr cummulative

Killian, Luke, Zee, Wyatt, Grant, Gracie, Julian 2.5 hr: Zee, Wyatt 2 hr: Killian 1.5 hr: Luke 0.5 hr: Julian 0 hr: Grant, Gracie - Disassmble door pillar - Finish drilling extra rivet holes in elevator. Ready to deburr. - Have newbies Grant and Gracie practice drilling, reaming, and deburring. 275 hr cummulative

2.5 hr: Wyatt, Nolan, Isaac 1.5 hr: Will, Killian, Luke - Continue remedial work on elevator assembly; nearly ready to disassemble and deburr. - Study assembly sequence of control rods (not obvious); remove powder coat from mixer's bearing areas, lubricate, assemble mounting brackets, and assemble the lot back in to the fuselage. 266 hr cummulative

2.5 hr: Nolan, Isaac, Killian 1.5 hr: Will 0 hr: Julian (had to leave early, introduced to inventory scheme) - Test wiring of the trim tab. Finish fitting last aluminum bits to elevator. - Work on flap motor mounting. 254 hr cummulative

1 hr: Nolan, Paxson, Luke, Killian - Discuss fuel line routing for about an hour. - Continue assembly of elevator, with discussion of wiring to trim tab. - Fit right cabin side (filing and reamer). 245 hr cummulative

2 hr: Paxson, Killian - Continue working on the mount for the controls mixer. - Assemble trim tab and other parts (including one replacement) on the elevator. - Lecture on electrical connections (Julian arrived in time for this). 241 hr cummulative

1 hr: Paxson 2 hr: Will, Nolan, Isaac, Killian - Resume work on elevator (Rob has returned). - Start to install flapperon mixer. - Finish reamering the left attach bracket of the rear carry through spar. - Start to install the reinforcing brace in the rear door posts. - Discussion of engine options. ULPower 350i selected. - Julian arrives for an introduction to the shop. He'll join us next month on the build. 237 hr cummulative

4 hr: Killian 2 hr: Paxson, Luke, Will 1 hr: Matthew 0.5 hr: Wyatt, Zee (training completed) - Gather and deburr cabin parts. - Store steel parts received from powder coater. - Begin fitting of flaperons mixer linkages. - Complete fitting of baggage bay pieces. 228 hr cummulative

1 hr: Paxson, Matthew, Nolan, Luke 3 hr: Killian 0 hr: Wyatt, Zee (training) - More baggage bay fit up. Deburr the aft tail cone and drill the rudder bracket. - Test fit cabin lower sides to tail cone. File slots on left side to better fit. Right side fits fine. 216 hr cummulative

2.5 hr: Paxson, Killian - Fashion clips to hold down the conduit for the trim tab wiring. - Finish fiddling with top sheet fit. Reamer A5 holes up to correct size. - Continue building up the baggage bay—lots of little parts. 209 hr cummulative

1.5 hr: Matthew 2 hr: Will, Paxson, Nolan 3.5 h4: Killian - Finish preparing steel parts for the powder coater. - Continue fitting parts for the baggage bay. Find the controls may be difficult to insert once the bay is riveted in. 204 hr cummulative

1 hr: Matthew, Luke, Will 2 hr: Paxson 4 hr: Killian - Fit h. tail brackets, which were incorrectly drilled at the factory. - Fit and deburr upper and lower baggage bay sheets, angles, and posts. - Fuselage top sheet left is too wide; begin to file/sand and fit. - Study plans trying to figure out how the above fit together. 193 hr cummulative

1.5 hr: Killian, Paxson, Matthew, Will - Resume work on elevator internals. - Figure out how to run elevator trim wiring bundle down the fuselage. - Assemble baggage bay back sheet. Will need to up drill some rivet holes to compensate for overly deburred skins. (Included debate as to whether this is necessary.) - Discuss with the teens engine options. 184 hr cummulative

2 hr: Paxson, Nolan, Matthew, Luke 4 hr: Killian - Cleco top skin of tail cone in place. Prepare baggage back and stiffeners. - Begin to break the corners of steel parts ahead of drop off at powder coater. 178 hr cummulative

2.5 hr: Killian, Luke, Nolan, Isaac - Deburr top skin and stiffeners; cleco. One stiffener/bracket was not fully drilled, and Rob will demonstrate the fix next week. - Cleco aft bulkheads to bottom skin. Cleco side skin assemblies to bottom skin. - Prepare rear spar carry-though and cleco. 166 hr cummulative

2.5 hr: Paxson 4.5 hr: Isaac 5 hr: Killian - Clean, deburr, and cleco both left and right sides of aft fuselage. Pull top side from storage and begin deburring. 156 hr cummulative

2 hr: Luke, Will 5 hr: Paxson - rivet belly together - collect parts for right side 144 hr cummulative

5 hr: Paxson, Isaac - cleco entire fuselage bottom, disassemble, deburr, clean, cleco, begin riveting 135 hr cummulative

1 hr: Bryce 3 hr: Will 4 hr: Paxson, Isaac, Nolan 5 hr: Killian - Lecture on deburring: Close inspection of elevator skin reveals we must double the number of rivets to compensate for the awful job of deburring. - Fit internal members of the elevator. - Finish map box; store in the attic. - Collect fuselage bottom skin parts from the attic and begin layout. Deburr bottom skin (huge burrs). Begin to cleco up on picnic tables (main build table is occupied with the delayed elevator assembly). 125 hr cummulative

2 hr: Mae, Carter 3 hr: Isaac, Nolan, 4 hr: Killian - Attach and drill elevator to stabilizer; deburr (not the best). Fit plastic tips to stabilizer. - Cleco, drill, and deburr instrument panel's map box: Ready to rivet once panel is available for test fit. 104 hr cummulative

2 hr: Afzal 3 hr: Will 4 hr: Carter 5 hr: Isaac, Nolan - Finish stabilizer skelton riveting. Rivet down second side of stabilizer skin. Drill elevator hinge into stabilizer. - Collect parts, deburr, assemble fin. 90 hr cummulative

1 hr (net): Paxson, Killian, Matthew, Luke, Afzal - It was decided the poor deburring was not a safety hazard (although it may affect longevity); proceeded with A4 rivets. - Rivet on half the skin of the stabilizer and prepare the front spar angle brackets. 71 hr cummulative

3 hr: Isaac, Nolan, Carter 4 hr: Paxson, Will 2 hr: Bryce - rivet up the stabilizer skeleton - deburr and cleco the elevator - deburr stabilizer skin; too deep in places, but factory authorized drilling up to A5 66 hr cummulative

3 hr: Bryce, Isaac - stabilizer: finish deburring, begin to rivet skeleton together 47 hr cummulative

2 hr: Will 3 hr: Matthew, Paxson, Luke - deburr horizontal stabilizer, cleco up 41 hr cummulative

3 hr: Nolan, Isaac - rudder completed! 30 hr cummulative

3 hr: Nolan, Isaac - rudder tip problems, deburring skeleton 24 hr cummulative

3 hr: Mae, Carter, Nolan, Isaac, Bryce - Nolan, Isaac, and Carter on the rudder skin; ran into trouble drilling the holes in the plastic top rib, drilled to A5 - Bryce and Mae on inventory (0 hr building) 18 hr cummulative

2 hr: Killian, Matthew, Afzal, Paxson - assemble shelving; begin inventory of Cruzer fuselage and finishing kits (0 hr building) 9 hr cummulative

3 hr: Carter, Nolan, Isaac - rudder skeleton finished 9 hr cummulative