The November meeting will be the Annual Meeting where a new board is elected and a budget approved. We need 13 voting members present to form a quorum. Failing to reach a quorum, we'll have to resort to a process by mail, so please attend if you can. With the hangar doors closed for the weather and discussions likely, this would be a good time to bring a mask to the hangar.

Please note the meeting date is November 7.

The proposed budget for 2021 will be e-mailed to everyone next week, ahead of the Meeting.

At the October meeting, a voting quorum was (barely) present, and the membership discussed and approved placing a plaque naming the chapter hangar in honor of Sam Sisk. A duplicate plaque will also be presented to Sam. In the mid 1990s, Sam, as chapter president, led the effort to arrange for a hangar as a permanent chapter home.

The treasurer gave a quick overview of finances and youth projects. He then read a handwritten letter of thanks from Brady Neuhalfen, who had received an $800 donation from chapter members to continue his flight training and is now ready to take his check ride. An excerpt follows:

I owe a lot of my progress to you, the Peoria Chapter of EAA, and I can't thank you enough for all of your help and generosity. I was honored to be selected to apply for the Ray Aviation Scholarship administered by Peoria EAA. While the scholarship went to another great young pilot, I received $1000 for flight training, and that meant a great deal to me. I am so grateful for having that chance and for receiving so much help from you in the process.

Eliza Fletcher, the 2020 Ray Scholar at 563, was presented with a shirt, hat, and Lightspeed Zulu ANR headset for completing the program. Congratulations again to Eliza for her impressive performance this past summer.

Eliza tries her new ANR headset

Former chapter member Roy Paget, who owns a floatplane, spoke on behalf of the KDB group leading the effort for a seaplane base on the Illinois river near Spring Bay, on Sankoty cove. FAA certification is expected to take several months. Because the proposed base is within 5 miles of an existing airport, namely 3MY, approval is not a given. Discussions have also begun with the state of Illinois, and the mayor of Spring Bay is already in favor of the base. It is hoped such a base will attract seaplanes passing through the area. Peter at Allmond plans on giving instruction at the base. Rob noted there is at least one amphibian at C75.

A second speaker was Mary Burris, a candidate for the Illinois Senate, who asked to speak to the group about her campaign positions.

In the video which followed the meeting, HQ noted attendance at their numerous webinars is well up this year.

Lincoln Land Community College sent a small packet of gifts to acknowledge our scholarship for their aviation mechanics program. Included is a 5x7 picture frame, a facemask, their refrigerator magnet, a thank you card, and a bag of caramel popcorn and two cookies. The first member to make a small donation gets the lot. Act fast while everything is fresh.

This month's VMC Club video topic is "Spot Landing in Tacoma":

This power-off landing is just for bragging rights at a local spot landing contest. You could win it if you adjust for the headwinds, yet an early error makes the target seem just out of reach. But maybe there's a way if you can make the right correction.The Club meets this Sunday, 11/1 at 6:00 in the hangar.

The IMC Club meets the following Sunday, 11/8.

David Leiting, the new Manager of Membership Development at HQ, has asked this month's chapter newsletters include an article he wrote about their new "Legacy membership campaign." An abridged version follows:

We all remember our mentor who introduced us to aviation and are forever grateful for the gift they gave us... Chapter members are the most engaged and passionate members you'll find within EAA. There is no better group than a local chapter to welcome a newcomer to EAA.

Once you identify whom you'd like to sponsor, simply visit this site to register EAA's newest member. After you give this membership, invite the individual to your chapter, and show them the opportunities and community that exist in their own backyard. By giving a membership and becoming a Legacy sponsor, you will receive a Legacy sponsor pin and patch.

Greg LePine has sent along a semi-annual update on his O-235 powered Corsair project:

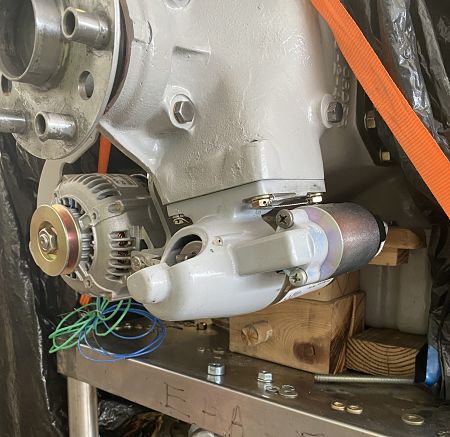

An alternator ordered for a 1985 Honda Accord 1.8L L4 60 amp had to be custom-fitted to the old generator mount bracket. The stock alternator bracket was too thin and flexed. Then the alternator was customized to be used with an external regulator. Letís not forget the alternator belt—it only took 6 to get the right one. The stock starter is just too heavy and securing a light-weight one for experimental was a no-brainer.

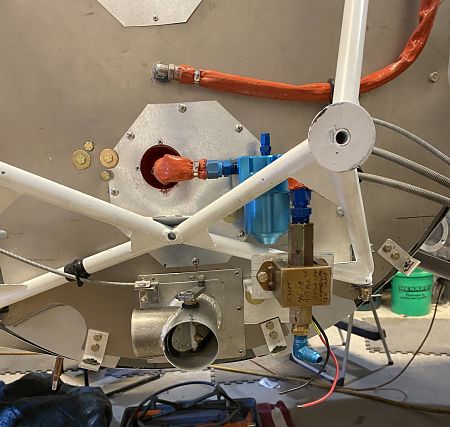

Before I could bolt on the engine, I had to finish the fuel system. So, I plumbed an on/off valve, bulk head fitting through the firewall to fuel strainer with water discharge, on to the Facet boost fuel pump (it's better to have it and not need it, than to need it and not have it).

Engine install: Moved wheeled table with engine to front of plane, moved engine crane in place. Hooked up and lift in place. All easily done after spending time to move all the wheeled tables, drill press and clear a path, after that itís a 15-minute job to fit it up and bolt it in place. Oh boy, I can hear engine noise. Well, almost.

I acquired a cross-over exhaust system for a Lycoming 0-235 / 0-360, and it needed to be fitted. That means you have to figure out a pieced-together header system that works for your project and keep it all within the cowling. It's just like anything else—cut a little off at a time and never force it to fit—and before you know it, it fits, you break out the TIG welder and tack it up. After removing the tacked-up pipes, I bolted it to a 1" piece of plywood and took it to a certified welder.

With the exhaust off to the welder, it's Mag time. We have a certified Mag rebuilder in the area who wants to retire but will teach you all about your mags. It was a great 9 hours of learning to take apart (without damaging or breaking anything) and putting it back together. We checked everything but only one item at a time until that was perfect. Yup, old school thinking and it works. Mags are perfect and installed and it only cost lunch.

Exhaust was returned from the welder and installed. Then I noticed the priming fuel lines on the wing were not installed. I know, would have been faster to install while the engine was standing on end.

Fitted up the carburetor to install a heat box. You all know the drill: Use what you have—don't reinvent it. Well, the carb heat air box with air cleaner was off a 0-360 engine and a little large. Well, a little cut here and there and refit here and there, it fits inside the cowl with an air filter.

Cowl fitting time. Both top and bottom cowls are held in place by removable hinge rod, and hinges are riveted in place. A round plywood circle was cut out and mounted to the propeller flange. The cowling forward position could be located. Securing it in place, it was time for a 6" adapter to fit the front fuselage to rear of cowling. Time to stand back and admire the long nose. With that done it was time to make an opening for the exhaust tube at each lower side. The material was cut and riveted in place with junk aluminum strips.

The lower cowl needed a bulge about 2½" like an old-style hood scoop but on the bottom. A nip and tuck here and cutting and lowering began. Securing all material in place again with junk aluminum strips. Cowl was removed and the inside fiber glassed to hold form. After it cured overnight it was reinstalled to make sure it still fit. It does.

The outside needed to be finished with foam, glass bead filler and final fine fiberglass. The finished lower cowl only gained 8 oz. of weight. I've just finished the top cowl oil access door.

It appears likely the airport will purchase canopies for the picnic tables we installed up by the FBO. The airport board is also interested in a proposal Greg made to mount an airplane hull on a pedestal near the parking lot. This would take much work on our part, not the least of which is finding a suitable hull to mount. Finding a licensed Professional Engineer to donate time for the project will be quite a challenge, but contact the board if you know one who is a pilot. Perhaps a mechanical engineer in the chapter would be interested in doing a preliminary study of wind loads on the pedestal, etc. Interestingly, the month after Greg mentioned this to the airport board, HQ published an article about a chapter in Pennsylvania which recently completed such a project.

Another recent article from HQ discussed the pilots who make an airport a more inviting place to visit. Along that line, I'll note any time I see a kid looking at airplanes through the chain link fence by the FBO, I offer to walk him up to the airplane and describe it's major components. The parents usually end up with a big smile.

Signature has been inspecting power lines with one of their Hughes 369D helicopters. One was seen hovering by the FBO after maintenance work. It does blow grit towards your lunch.